Innovations in Drywall Taping Technology: Revolutionizing the Construction Industry

Innovating Drywall: Advanced Taping Techniques for Modern Construction

The construction industry is constantly evolving, with new materials and techniques emerging to streamline processes and enhance outcomes. One such area of innovation lies in the realm of

drywall taping technology. Drywall, a staple in modern construction, relies heavily on taping for both structural integrity and aesthetic appeal. Traditionally, this has involved standard tape for packaging, but recent advancements are changing the game.

The Evolution of Drywall Tape

Gone are the days when the only option was conventional paper tape for packaging. The industry is now witnessing a surge in custom tape for packaging, tailored to specific drywall needs. This shift is not just about strength and durability; it's about integrating functionality with aesthetics.

Customization and Branding

The concept of branded tape for packaging has infiltrated drywall taping. Professionals can now choose tapes that not only serve structural purposes but also reflect branding. This innovation is particularly beneficial for companies looking to enhance their brand visibility in every aspect of their work.

Material Advancements

The types of tape for packaging used in drywall have expanded beyond paper. New materials offer improved flexibility, adhesion, and ease of application. These tapes reduce labor time and provide longer-lasting results, which is crucial in high-traffic or moisture-prone areas.

Printing Technologies

Printing on tape for packaging is another frontier. Advanced printing techniques allow for the inclusion of helpful guides directly on the tape, such as measurement marks or installation instructions. This not only speeds up the installation process but also ensures greater accuracy, minimizing the risk of errors.

Specialized Tapes for Different Needs

Innovation in drywall taping also means developing specialized tapes for varying requirements. For instance, certain tapes are now designed to withstand extreme temperatures, while others are focused on eco-friendliness, catering to the growing demand for sustainable construction materials.

The Future of Drywall Taping

As we look ahead, the potential for further innovation in drywall taping is immense. We might see smart tapes equipped with sensors to monitor wall integrity or even tapes that change color based on humidity levels. The focus will likely continue on enhancing efficiency, sustainability, and adding value beyond mere functionality.

Enhancing Efficiency and Sustainability in Drywall Taping

The ongoing advancements in drywall taping technology are not only revolutionizing the construction process but are also paving the way for more efficient and sustainable practices. The introduction of advanced materials and techniques is significantly reducing the time and resources required for drywall installation and repair.

Technological Integration

The integration of technology into drywall taping is a significant leap forward. Innovations like tapes with embedded QR codes or augmented reality markers enable workers to access installation guides or instructional videos instantly, directly at the construction site. This integration of digital tools ensures precision and can significantly reduce the learning curve for new workers.

Eco-Friendly Options

Sustainability is becoming a core consideration in construction materials, including drywall tape. The market is now seeing a rise in eco-friendly tapes, made from biodegradable or recycled materials. These options not only reduce environmental impact but also appeal to environmentally conscious clients and projects aiming for green certifications.

Enhanced Durability and Performance

Modern tapes are designed to offer enhanced durability, reducing the need for frequent repairs and maintenance. Some tapes are now infused with mold-resistant chemicals or fire-retardant materials, adding an extra layer of safety and longevity to the construction.

Customization for Specific Environments

The diversity in types of tape for packaging extends to drywall tapes designed for specific environmental conditions. For instance, tapes suited for high humidity areas or extreme temperature fluctuations are becoming more common. This customization ensures that irrespective of the location, there is an appropriate, high-performing taping solution available.

Artistic and Decorative Applications

In addition to their structural roles, these new tapes are being used for artistic and decorative purposes. With the ability to print on tape for packaging, designers and architects are now using decorative tapes as an element of interior design. These tapes can be used to create patterns or textures on walls, offering a unique and creative alternative to traditional painting or wallpaper.

The Role of Feedback in Innovation

Feedback from professionals in the field plays a crucial role in driving these innovations. Manufacturers are continuously working with drywall installers, contractors, and architects to understand their needs and challenges. This collaborative approach ensures that the new products are not only technologically advanced but also practical and user-friendly.

The Impact on the Industry

These innovations in drywall taping technology represent a significant shift in the construction industry's approach to materials and methods. They reflect a broader trend towards efficiency, sustainability, and customization. As these technologies continue to evolve, they promise to further streamline construction processes, reduce environmental impact, and open up new creative possibilities in building design and aesthetics.

Looking Ahead

The future of drywall taping technology is bright and filled with potential. As we continue to innovate and integrate new materials and digital tools, the construction industry stands on the brink of a new era of efficiency, sustainability, and creativity. These advancements are not just about improving the way we build walls; they're about reshaping the very fabric of construction to meet the demands of the modern world.

Ready to work with Dallas Drywall Solutions?

Let's connect! We’re here to help.

Send us a message and we’ll be in touch.

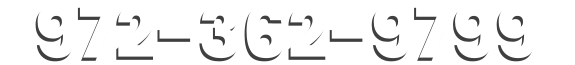

Or give us a call today at 972-362-9799